When a print completed the design and layout, everything is ready to go into the printing process. Howeve, before the mass production, the prepress processing steps will be an important and indispensable part from the idea to the final product. Prepress processing will be used on the one hand to check the praticability of the design draft; on the other hand, establish standards for formal print production processes. After prepress processing, we will make a comprehensive consideration of the work from the perspective of production and production.

As the pre-press processing standard established by Artron Graphic Arts, the color of the printed matter will be processed to facilitate the printing process. If problems are found during prepress processing, feedback will be communicated to the customer timely to ensure that the production results are in line with customer expectations and delicated to achieve “zero error”.

Step 1: Book form, at a glance

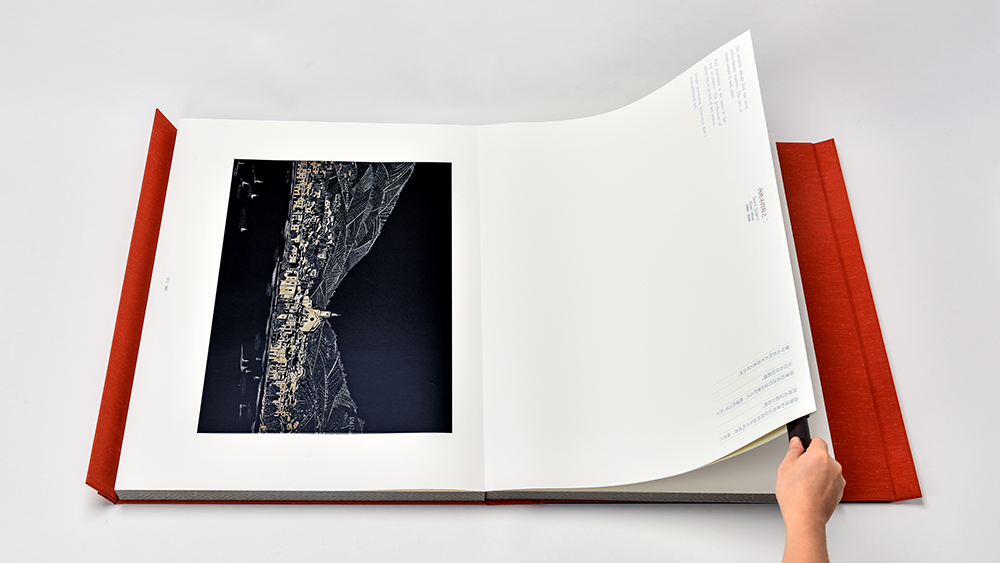

After completing the planning and pre-press processing steps of the printed matter, we can finally start to look forward to seeing the prototype of the final printing products, which we were call White Sample. As a printing supplier that is delicated to make every step to be perfect, especially in terms of color and quality, Artron Graphic Arts believes, Every detail matters.

Whether the client is requested for an illustrated hardcover book, a visually stunning collection of photos, a simple but exquisite invitation, or a brand manual or album for a brand, White Sample will be send to the client before going into the mass production.

When you get the White Sample, the print will be presented in physical form for the client to confirm. The details of size, paper, material, binding method, etc. are all presented in White Sample. All the creative ideas and the imaginations will be seen and touchable.

Different sizes give the prints distinct temperament and functions - pocket books are portable and compact, regular size books are neat and authoritative, and big books passes a style of enormous, majestic and premium. Behind each size, it requies for different production logic and technical requirements, such as making technology, operating procedures, and binding methods etc.

Artron Graphic Arts can meet the individual needs of customers in terms of size. The size that can be printed from minimum 130*184mm to maximum 500*685mm. The largest size book that can be printed by Artron is almost equivalent to half a person in size. And it taks 2-3 people to move. Whether it is used for shop window decoration, exhibition display or space decoration, it can become a bright spot and focus in the space.

In addition to the functions of display and decoration, the book also has its irreplaceable value of collection. Many brands and companies will make a big book at a special moment to fully display the spirit and value of the brand in the ‘book’ format. The big book projects executed by Artron Graphic Arts include: Apple, Manchester United, Chanel (picture display and jump introduction for each project).

For the user, binding is a part of the the printing process that with low sense of existence. People always takes for granted that a book or print should be strong and solid. Good binding is to let the reader feels “NO existence of binding", the reading rhythm is not disturbed when the reader flips through the inner page, and the book will not be scattered because of frequent reading. The binding process of Artron Graphic arts is also delicatied to make the reader cannot reliaze its existence: even picking up any page, the rest of the inner page and the cover will not be scattered.

However, "solide and firm" is not the only measure of binding quality, the number of binding process types is up to hundreds of, and corresponds to the needs of different prints. For the thinness, function, type and use scene of the printed matter, different binding methods bring different reading experiences, which will also bring out the different overall temperament of the printed matter.

Artron Graphic Arts has many years of experience in the binding process, and has guaranteed its quality and standard by the introduction of equipment and the training of technicians. Some of the printed products, such as oversized books, fine art books and other books that with special collection value, have higher requirements for the binding process, and even binding will become an important part of its aesthetic expression. Artron Graphic Arts can deeply understand the customer's demand for aesthetic communication, and strives to present the product perfectly.

Paper is the most important material of printed matter, and the most basic unit is also the most basic physical form that carries the content of communication. From the perspective of the senses, the thickness, weight, texture, material and color of the paper play a decisive role in the overall printing effect. From the manufacturing process, the paper will have a direct impact on the final appearance of the prints,such as color management, binding process, etc.

Artron Graphic Arts provides their customers with a wide range of paper choices and professional advice on making the right choice to match customers’ expectaions. Artron Graphic Arts has deep understanding and insight into how paper affects the charateristics of works and produces the best results. Different works of art have their own special textures - oil paintings are thick and staggered; Chinese ink paintings are minimal and elegant; the light and shadow of photography are very subtle, commercial brands need the details to be appealing... Find the paper that can make the most appropriate expression of the work, and ensure that the printing process can be smooth and unobstructed. It is the principle and goal of Artron's art printing on paper selection.

More and more prints are expected to be personalized in their production to accurately highlight the expressiveness and appeal of the content. The chic finishing process is the finishing touch of prints: for example, bronzing and hot silver make prints more eye-catching; while the “second eye” process of embossing and embossing creates a low-key luxury for paper products. There are some special finishing designs and processes that even become the expression of beauty and content itself, and increasingly highlight the value of special crafts in print production.

The types of special crafts are numerous, and some special crafts are even entitled as "intangible cultural heritage", which is the ingenuity of generations of craftsmen. Artron Graphic Arts has always expressed sincere respect and attention to special crafts and inheritors. In addition to develop a standing hand-made bookmaking workshops in Beijing, Artron also regularly launches activities related to the topics of special crafts. At the same time, Artron Graphic Arts and some special crafts inheritors have long-term good cooperative relations, which can serve clients' individual needs and create unique products and values for the them.

Step 2: Professional color management, accurate color expression

The color sample, corresponding to the white sample, is mainly used to calibrate the color. Artron Graphic Arts do value the ‘color sample’, because it it is an important step to confirm the color style of the printed matter with the customer. Artron Graphic Arts always believes that accurate color expression is essential for the communication of artistic content. It is always the subject of Artron's research and the direction of efforts to accurately display the subtle color differences, color levels and convey color emotions in the prints.

When received a color sample, the artist or brand that is critical to the color can judge the quality of a print supplier and communicate and adjust it according to their requirements. For print manufacturing manufacturers, behind the color samples are the data and standards of the whole production system. This color sample will be related to a complete set of production management systems - printing equipment parameters, ink ratios, paper parameters, operating procedures and pre-set test results for the production environment.

Understand color is the basic to present color. In color management, Artron not only stays in the color sample output. Artron has been focusing on art printing services for more than 20 years. It has accumulated huge data on art works, and accumulated soft data from the perspectives of interpretation and color psychology, which enabled it to have the ability to understand color. In addition, Artron Graphic Arts has formed its own standardized and professional color management process. Furthermore, Artrona owned 2 unique printing technology patents - CHROMA and SEPIANA, becoming the benchmark in color pringting and black and white printing.

The first step: image interpretation. Read color information, use big data to find the best comprehensive solution and data results for the color of the current work, and make fine adjustments in combination with human eyes.

The second step: color information extraction. The color information is converted into a printing language, the ink, paper, and equipment parameters are adjusted correctly, and the lithographic parameters used in the formal production are simulated into a digital printing machine to print out the color proofs.

Patented technology

CHROMA centric

SEPIANA showing

ArtCharm

copyright reserved 2018 Artron Art Group Copyright Guangdong ICP Preparation 06016259 Beijing Public Security Preparation 110105012903